We have a variety of storage and ripening facilities that are essential for the delivery of fresh, safe, delicious fruits and vegetables to consumers.

We have a variety of storage and ripening facilities that are essential for the delivery of fresh, safe, delicious fruits and vegetables to consumers.

Ripening Room

Funasho Shoji has ripening rooms where fruits are ripened to the degree requested by each client. A variety of bananas, avocados, mangoes, and other fruits are ripened in these rooms to the optimal level.

Banana Ripening Room

The processing of bananas requires highly meticulous management,

experience, and technical proficiency.

Funasho Shoji focuses on the ripening of bananas by establishing banana ripening rooms.

Under a 365-day-a-year quality management program supervised by experienced technicians,

we achieve a stable supply of safe, secure, high-quality products.

These 13 rooms are designed on the basis of the size of large banana boxes to minimize reloading and to reduce the damage to bananas.

Green bananas are carefully ripened in the banana rooms.

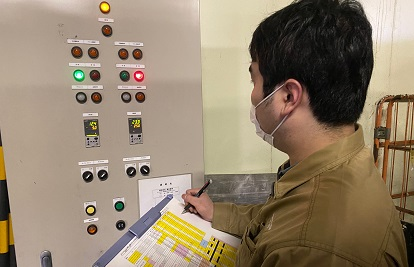

It is difficult to manually control the temperature for bananas whose ripeness levels vary with the load received.

Therefore, experienced Funasho Shoji technicians control the room temperature with utmost care 365 days a year while checking the ripeness level of bananas in each room.

high-quality bananas to consumers,

green bananas are ripened

in the banana rooms every day.

Ripening Room

Fruits other than bananas that require ripening are processed

in the rooms on the first floor of the headquarters building.

The facilities comprise a ripening room and a cooling room.

The ripening room is on the right in the photo and the cooling room is on the left.

Temperature control is essential for avocado processing. The optimum processing method changes depending on the outside temperature and the condition of the item, so a skilled caretaker makes an assessment every day.

The item quality is checked by its look and how it feels, but it is a very difficult task. We check every day to see if the selection was correct